Agitators for Industrial Mixers

VMI designs and manufactures a full range of agitators that are well suited to a variety of mixing operations. With over 70 years of experience in producing industrial mixing equipment, we ensure our agitators perform at top standard.

To match you with the right agitator, our teams carefully study your processes regarding dilution, dissolution, suspension, homogenization, dispersion, and emulsion. Then, we define the right sizing, power, and speed parameters for any liquid-liquid or solid-liquid mixtures. Our goal is to help you achieve a high-quality end product and optimize your processes for productivity.

A variety of agitator blades (radial, axial, mixed, or peripheral) helps optimize movement and shearing, no matter the volume or rheological characteristics of your product. These agitators are specifically designed to adapt to and equip VMI industrial mixers.

Agitation Mobiles for Emulsion Processes

The Ultramix agitator is suited for all emulsion operations and guarantees a high stability of phases thanks to its intense shearing capabilities. The stator geometry is adapted to product viscosity.

The bowl bottom emulsifier (EFC) consists of a rotor stator and may be associated with an agitator of the Cynabloc type, which is located on the top of the vessel to ensure the circulation process.

For relatively significant production runs (from a few hundred liters per hour and to several tens of thousands of liters per hour), continuous mixing is undeniably an interesting alternative for batch mixing operations. VMI offers continuous mixers that come in a variety of models to meet your unique needs for mixture homogeneity and ingredient amount:

- The EHL agitator is made of one or more rotor-stators and enables both emulsion or smoothing operations.

- The gyroflux agitator manages all mixing operations (dispersion at high speed, dilution, etc.).

Agitation Mobiles for Dilution and Homogenization Processes

The Dynabloc agitators manage dissolution, dilution, or homogenization operations for bowls of intermediate capacity. They come with turbines to combine pumping and shearing capabilities.

Agitation Mobiles for Dispersion Processes

Dedicated to dispersion operations, the Direct and Empateur agitators (for small and large product volumes, respectively) are characterized by their high agitation speed combined with a dispersion turbine that possesses radial effects.

The bowl bottom disperser (DFC) is located on the bottom of the bowl. It may be associated with an agitator of the CYNABLOC type, which is located on the bowl’s roof to ensure a pumping function.

The Direct, Empateur, and DFC agitators are ideal for dispersing non-soluble powders in solid/liquid mixtures.

Agitation Mobiles for Suspension and Homogenization Processes

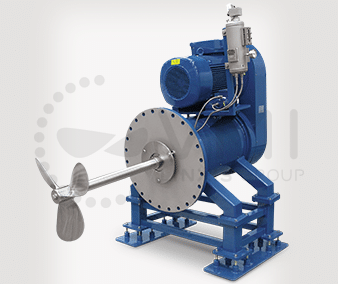

Cynabloc agitators are known for their high pumping efficiency. Thanks to the performance of propellers with axial effects, the agitators are perfect for homogenization and suspension operations, even for large batches.

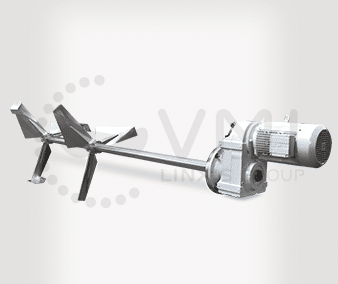

Our range of Helibloc agitators is recommended for homogenization or suspension operations using high-capacity containers. The agitator sets up in a lateral position on the bowl ferrule.

These agitators are recommended for mixtures that require solid/liquid ingredients with non-soluble powders.